Understanding GRP Grating

What is GRP Grating?

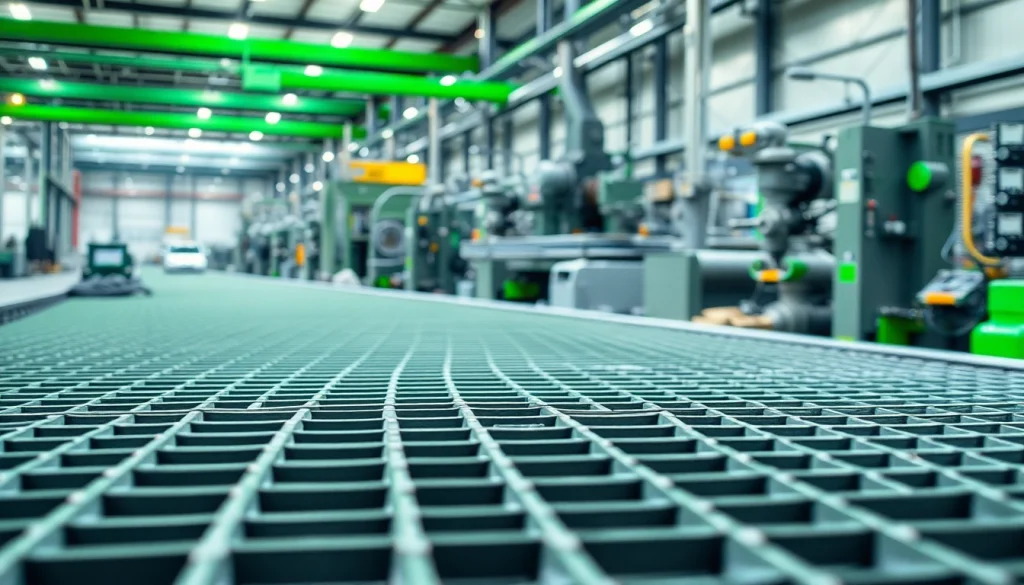

Glass Reinforced Plastic (GRP) grating is a composite material constructed from fiberglass and resin, designed to provide a lightweight yet robust alternative to traditional metal grating. This type of grating is engineered for performance, offering excellent mechanical properties while also being resistant to corrosion, chemical attacks, and unanticipated environmental challenges. GRP grating comes in various forms, including molded and pultruded variants, making it versatile for diverse industrial applications.

Benefits of Using GRP Grating

The advantages of GRP grating are numerous. First and foremost, its lightweight nature reduces the load on structures while simplifying transportation and installation processes. GRP grating is also remarkably resistant to chemicals, making it ideal for use in environments where exposure to harmful substances is a concern. Additionally, its non-conductive properties enhance safety in electrical applications, and the slip-resistant surfaces ensure safety in workplaces, reducing the risk of accidents.

Moreover, GRP grating offers exceptional durability, with a lifespan significantly outlasting that of traditional materials such as steel and wood. The lack of rusting and the ability to withstand extreme temperatures further contribute to its desirability. Taken as a whole, these qualities make GRP grating a superior choice for various industrial applications.

Common Applications

GRP grating finds utility across numerous sectors due to its distinctive properties. Common applications include:

- Walkways and Platforms: Frequently utilized in industrial settings for safe pedestrian access.

- Drainage Covers: Employed in water treatment and chemical processing plants for efficient fluid management.

- Corrosive Environments: Perfect for use in chemical plants, pulp and paper mills, and offshore platforms.

- Access Covers: Often used in HVAC systems and flooring solutions.

Choosing the Right GRP Grating

Factors to Consider When Selecting GRP Grating

When choosing the right GRP grating, several factors must be weighed:

- Load Requirements: Different applications have varying load-bearing capacities; select grating that meets or exceeds requirements.

- Environment: Consider the environmental conditions, such as temperature fluctuations, exposure to chemicals, and UV resistance needs.

- Thickness and Configuration: Determine the thickness based on application-specific demands for strength and stability.

- Surface Treatment: Slip-resistance is critical for safety; ensure the grating has adequate surface treatment for traction.

Comparison of GRP vs. Other Grating Materials

Comparing GRP grating with other materials such as steel and aluminum provides insights into its benefits. Unlike steel, GRP is lightweight, does not corrode, and requires much less maintenance, making it a cost-effective choice over time. When juxtaposed with aluminum, while both are lightweight, GRP typically outperforms in chemical environments due to its resistance to a broader range of corrosive substances.

Tips for Sourcing a Reliable GRP Grating Supplier

Finding a reliable GRP Grating Supplier can significantly impact overall project success. Here are some effective tips:

- Research Credentials: Investigate potential suppliers’ industry certifications and experience.

- Customer Reviews: Seek testimonials or case studies from previous clients to gauge reliability.

- Product Range: Ensure they offer a diverse range of GRP products tailored to specific needs.

- After-Sales Support: Assess the level of customer support post-purchase to address any issues that may arise.

Installation Guide for GRP Grating

Preparation Steps for Installation

Preparing for the installation of GRP grating is crucial to ensure a smooth process. Here are steps to undertake:

- Site Assessment: Evaluate the installation area for obstacles and calculate the necessary grating size.

- Gather Tools and Materials: Ensure all tools, such as a saw, drill, and appropriate fasteners, are available.

- Cleaning the Surface: Clear debris and dust from the installation site to guarantee a clean surface.

Step-by-Step Installation Process

Once everything is in place, follow these installation steps:

- Cut the grating panels to required dimensions using a suitable saw.

- Position the panels in place, ensuring they are aligned correctly.

- Secure each panel using the specified fasteners, maintaining uniform spacing.

- Check for level and stability, making adjustments as necessary.

Post-Installation Maintenance Tips

To sustain the integrity and functionality of GRP grating, regular maintenance is essential. Consider the following tips:

- Regular Cleaning: Clean grating surfaces periodically to remove debris and contaminants.

- Inspect Fasteners: Regularly check the fastening system to ensure that everything remains secure.

- Evaluate for Damage: Conduct routine inspections for signs of wear or damage, addressing issues promptly.

Performance Metrics of GRP Grating

Load-Bearing Capacity

Understanding the load-bearing capacity of GRP grating is essential for ensuring safety and meeting regulatory standards. Generally, factors affecting load capacity include the grating thickness, panel size, and spacing of supporting beams. Manufacturers typically provide load tables for reference, making it easier to choose the right grating for specific applications.

Longevity and Durability Assessment

GRP grating is engineered for long life, often exceeding that of traditional materials. The durability of GRP can be attributed to its resistance to physical wear and environmental degradation. Longevity assessments must consider the application’s specific environmental conditions to project accurate lifespans effectively.

Environmental Considerations

Choosing GRP grating also contributes positively to environmental sustainability. The material is typically made from recyclable components and minimizes the need for chemical preservatives. Therefore, its use in various industries can help organizations maintain eco-friendliness while benefiting from its performance characteristics.

Frequently Asked Questions About GRP Grating

What makes GRP grating ideal for industrial use?

GRP grating is resistant to corrosion, non-conductive, lightweight, and slip-resistant, making it suitable for harsh industrial environments.

How do I maintain GRP grating?

Regular cleaning, inspecting for wear, and ensuring fasteners are secure are key aspects of maintaining GRP grating longevity.

Can GRP grating be customized for specific projects?

Yes, GRP grating can be customized in size, thickness, and surface treatment to meet project-specific requirements effectively.

What are the load limits of GRP grating?

Load limits vary by grating design, thickness, and panel support spacing. Refer to manufacturer specifications for precise load capacities.

Where can I source GRP grating materials?

GRP grating materials can be sourced from specialized suppliers focusing on industrial and construction markets.